Extrusion process parameters include temperature, pressure, extrusion rate, and traction speed.

Temperature

Temperature is one of the important conditions for the smooth progress of extrusion molding. Starting from a powdery or granular solid material, the high temperature product is extruded from the handpiece and undergoes a complex temperature change process. Strictly speaking, the extrusion temperature should refer to the temperature of the plastic melt, but the temperature depends to a large extent on the temperature of the barrel and the screw, and a small part comes from the frictional heat generated when mixing in the barrel, so often The barrel temperature is approximated to indicate the molding temperature.

Since the temperature of the barrel and the plastic are different in each section of the screw, in order to smoothly carry out the process of conveying, melting, homogenizing and extruding the plastic in the barrel, in order to efficiently produce high-quality parts, the key problem is to control well. The temperature of each section of the barrel and the temperature adjustment of the barrel are realized by the heating and cooling system of the extruder and the temperature control system.

The temperature of the head must be controlled below the thermal decomposition temperature of the plastic, and the temperature at the die can be slightly lower than the temperature of the head, but the plastic melt should have good fluidity.

In addition, the temperature fluctuations and temperature differences during the molding process will cause residual stresses in the plastic parts, uneven strength of the dots, and dullness of the surface. There are many factors that cause such fluctuations and temperature differences, such as heating, cooling system instability, screw speed changes, etc., but the screw design and selection have the greatest impact.

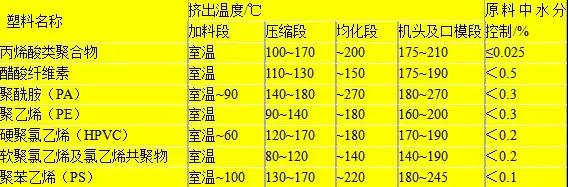

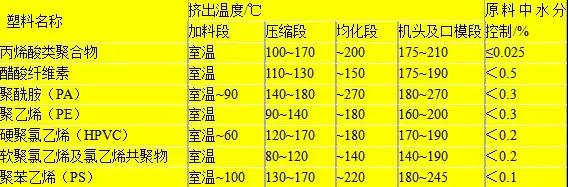

Table 1 Temperature parameters of several thermoplastic extruded tube, sheet and sheet and film

2. Pressure

During the extrusion process, due to the resistance of the flow, the change in the depth of the screw groove, as well as the filter screen, the filter plate and the die, and the like, a certain pressure is generated inside the plastic in the direction of the axis of the cylinder. This pressure is one of the important conditions for a plastic to become a homogeneous melt and to obtain a dense plastic part.

Increasing the head pressure can increase the mixing uniformity and stability of the extruded melt and increase the density of the product, but excessive head pressure will affect the yield.

Like the temperature, the pressure changes with time will also produce periodic fluctuations, which also have an adverse effect on the quality of the plastic parts. The change of the screw speed, the instability of the heating and cooling systems are the causes of the pressure fluctuations. In order to reduce pressure fluctuations, the screw speed should be reasonably controlled to ensure the temperature control accuracy of the heating and cooling devices.

3. Extrusion rate

The extrusion rate (also known as the extrusion speed) is the mass (in kg/h) or length (in m/min) of the plastic extruded from the extruder die per unit time. The size of the extrusion speed characterizes the level of extrusion productivity.

There are many factors that affect the extrusion speed, such as the structure of the machine head, the screw and the barrel, the screw speed, the structure of the heating and cooling system, and the characteristics of the plastic. Both theory and practice have shown that the extrusion rate increases with the increase of the screw diameter, the depth of the spiral groove, the length of the homogenization section and the rotation speed of the screw, and increases with the melt pressure at the end of the screw and the gap between the screw and the barrel. In the case where the structure of the extruder and the type of plastic and the type of plastic part have been determined, the extrusion rate is only related to the screw speed. Therefore, adjusting the screw speed is the main measure for controlling the extrusion rate.

The extrusion rate also fluctuates during the production process, which will affect the geometry and dimensional accuracy of the part. Therefore, in addition to correctly determining the screw structure and size parameters, the screw speed should be strictly controlled, and the extrusion temperature should be strictly controlled to prevent the extrusion pressure and melt viscosity change due to temperature changes, resulting in fluctuations in the extrusion speed.

4. Traction speed

Extrusion mainly produces continuous plastic parts, so a traction device must be provided. The plastic parts extruded from the machine head and the die will undergo a tensile orientation under the action of traction. The higher the degree of stretching orientation, the greater the tensile strength of the plastic part in the orientation direction, but the larger the length shrinkage after cooling. Generally, the pulling speed can be comparable to the extrusion speed. The ratio of the traction speed to the extrusion speed is called the traction ratio and must be greater than one.

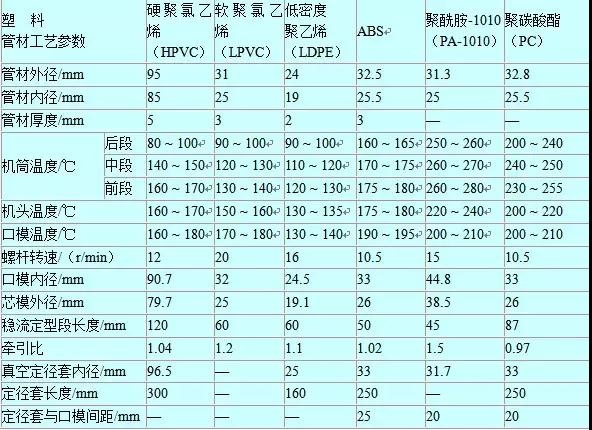

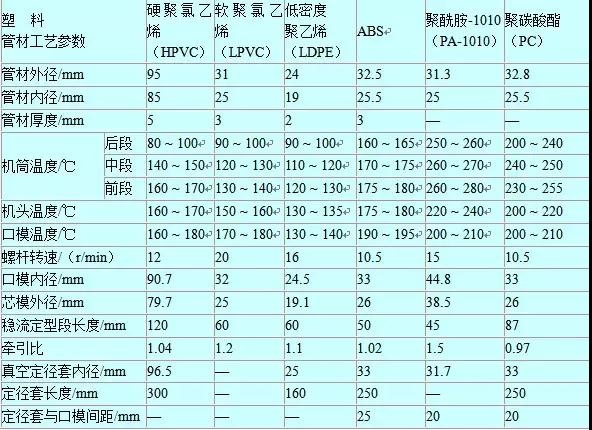

Table 2 Extrusion process parameters of several plastic pipes

2025 Chinaplas Shenzhen

2025 Chinaplas Shenzhen